Introduction

Small quantities of dangerous goods can be found in most workplaces.

Whatever they are used for, the storage and use of such goods poses a serious hazard unless basic safety principles are followed.

Then you must

º be aware of the hazards of various types of flammable substance;

º be aware of the basic standards, which apply to safe handling and storage of flammable substances;

º introduce procedures to prevent accidents and protect people from the hazards of flammable substances;

º find more detailed information when you need it.

There is an enormous variety of flammable substances to be found in the workplace.

They range from the obvious, e.g. petrol, paint thinners, welding gases and heating fuels, to the not so obvious, e.g. packaging materials, dusts from woodworking and dusts from food stuffs such as flour and sugar etc.

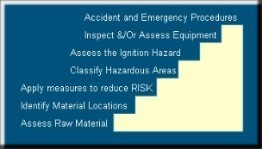

SAFETY PRINCIPLES

By applying the following five principles, courtesy of the Health & Safety Executive, www.hse.gov.uk you will be well on the way to making sure that you are working safely with flammable substances.

Ventilation (V)

Unsure there plenty of fresh air where flammable liquids or gases are stored and used?

Good ventilation will mean that any vapours given off from a spill, leak, or release from any process, will be rapidly dispersed.

Ignition (I)

Have all the obvious ignition sources been removed from the storage and handling areas?

Ignition sources can be very varied and they include sparks from electrical equipment or welding and cutting tools, hot surfaces, open flames from heating equipment, smoking materials etc.

Containment (C)

Are the flammable substances kept in suitable containers?

Will a spill will it be contained and prevented from spreading to other parts of the working area?

Use of lidded containers and spillage catchment trays, for example, can help to prevent spillages spreading.

Exchange (E)

Can we exchange a flammable substance for a less flammable one?

Can we eliminate flammable substances from the process altogether?

Think of other ways of carrying out the job more safely.

Separation (S)

Are flammable substances stored and used well away from other processes and general storage areas?

Can they be separated by a physical barrier, wall or partition?

Separating the hazards in this manner will contribute to a safer workplace.

Think about the flammable substances you have in the workplace and apply these five principles wherever possible.

Tell workers, and others who need to know, about the hazards and how they should control them.

Think - keep a strong grip on your workplace safety.

SPECIFIC MATERIALS

The following sections deal with specific types of flammable substances.

The precautions mentioned need to be considered in addition to the principles just described.

Flammable liquids

Flammable liquids can give off large volumes of flammable vapours at room temperature.

These vapours, when mixed with air, can ignite, often violently.

Spilled flammable liquids can, if not contained, flow a long way to an ignition source, and then flash back to the source of the leak.

Spills on clothing can represent a serious risk of injury if ignited. To help control these risks:

º store flammable liquids in a separate storage area, or in a purpose-made bin or cupboard;

º dispense and use them in a safe place where there is good ventilation and no source of ignition;

º keep containers closed when not in use. If possible, use safety containers, which have self-closing lids;

º dispense liquids over a tray and keep some non-flammable absorbent material handy to mop up spills;

º dispose of contaminated materials safely or call in disposal experts.

Flammable dusts

Finely divided flammable dusts dispersed in the workplace atmosphere can, if ignited, explode violently and cause a lot of damage.

If you handle flammable dusts you need to remember the following:

º keep plant dust-tight;

º keep the working area dust-free by regular cleaning, and vacuuming spillages as they occur;

º some dust handling plant has special safety features built in. The purpose of these needs to be properly understood, and they should be maintained in good working order.

Flammable solids

Some types of plastic foam, packaging materials, polyester wadding and textiles will ignite easily and burn fiercely, giving off a lot of dense black smoke.

Remember:

º do not store these materials close to heaters or electrical equipment, which could run hot and act as a local ignition source;

º make sure that gangways and exits from storage and working areas are kept clear of packaging materials, finished products containing flammable solids etc.

º In the event of fire, gangways and exits could become obscured by smoke, so the easier they are to find, the better.

Flammable gases

Gases in cylinders are often stored at very high pressures, and so their uncontrolled release can be physically dangerous.

A small amount of released gas can fill a large area with a potentially explosive mixture.

This is particularly true of liquefied gases such as LPG.

The following points need to be considered:

º stored cylinders need to be suitably restrained and their valves protected from impact damage;

º gas cylinders may need special valves, fittings and hoses.

º Always check the manufacturers' or suppliers' instructions and fit the correct equipment;

º protect hoses from potential causes of damage that could cut, scuff or weaken them. Examine them regularly and replace them if they show signs of damage or wear that could give rise to a leak.

Oxygen

Although oxygen is necessary for life and is an essential ingredient in controlled burning, such as in a gas fire or oxy-fuel gas welding and cutting, its misuse can lead to serious consequences.

Materials that ordinarily will burn only slowly will burn very vigorously in an oxygen-enriched atmosphere.

Others such as greases and oils may burst into flames in this kind of atmosphere.

As well as the precautions outlined above for flammable gases, the following points should be remembered:

º never use oxygen instead of compressed air;

º never use oxygen to sweeten the air in a working area or confined space;

º never use grease or oil on equipment containing oxygen.

Reactive chemicals

Some products contain chemicals, such as organic peroxides, which can explode if they are not stored and handled correctly.

Other substances can react vigorously with incompatible materials or contaminants.

For example, oxidising chemicals can cause flammable materials to ignite, and some substances, such as sodium, react violently with water and can ignite.

The following points need to be considered:

º storage and process temperatures may need to be carefully controlled to prevent dangerous decomposition or reaction;

º check labels and safety data sheets for physical properties and incompatibility with other materials.

EMERGENCIES

Whenever you work with flammable substances, there is the potential for something to go wrong.

You need to think about possible problems and make sure everyone knows what to do in an emergency.

Instructing staff in emergency procedures is an important part of their job training, and should be ongoing.

Examples of things to think about are:

º make sure workers know enough to prevent the mixing of incompatible chemicals;

º lay down the procedures to be followed if there is a leak or spill of flammable material and make sure people know and understand them;

º if special first-aid facilities or equipment are required, then staff need to be trained in their use.